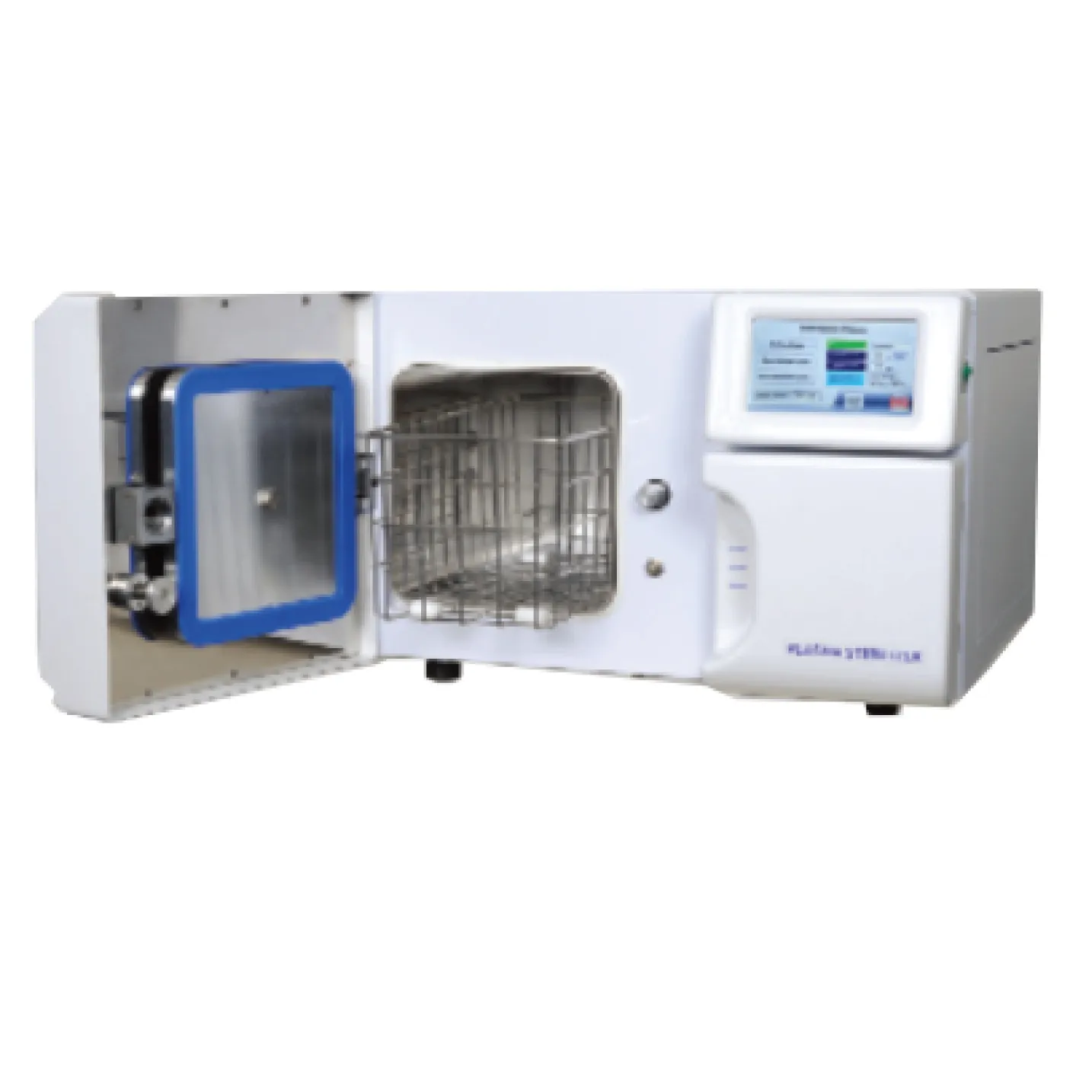

Plasma Sterilizer Autoclave MPS30

Prices are available to members only. Please log in or create a free account to continue.

Plasma Sterilizer Autoclave MPS30

The next-generation Plasma Sterilizer Autoclave offers an alternative to high-temperature

autoclaves, which limit the types of surgical items that can be sterilized. It is designed to

generate plasma by using hydrogen peroxide vapor diffusion technology, sterilizing all

surgical medical devices?both metallic and non-metallic material?at low temperatures

quickly (in less than one hour) and safely.

The byproducts produced are passed through a three-stage filter and a hydrogen

peroxide catalyst. Since they are converted into small amounts of oxygen and water

vapor at discharge, no separate ventilation process is required.

Features :

- The sterilizing agent is Hydrogen Peroxide (40?60 wt%).

- Automatically opens and closes the door with built-in inter-

locks that securely lock during the sterilization process. - Features 19 error alarms to prevent incomplete sterilization.

- Includes overheat protection,door interlock, and a sterilant

injection system to prevent leakage when the sterilizing agent

is desorbed. - Fully automatic sterilization control is provided via a micro-

processor with a 7-inch LCD touch display panel. - Achieves precise air removal using a pre-vacuum method;

since the by-products consist of only small amounts of water

and oxygen, additional ventilation is not required. - Offers excellent drying of residual moisture through a

pre-heat and mechanical ventilation system. - PCD tested for both metallic and non-metallic tools and

instruments.